Conveyor Package for FGD is a process of removal of sulphur dioxide (SO2) from flue gases of fossil-fuel based Thermal Power Plants and from other sulphur oxide emitting processes such as waste incineration.Fossil fuels such as coal contain significant amount of sulphur. Combustion of fossil fuel result in emission of SO2 and other pollutants. Generally, 95 to 96% of Sulphur in fuel is converted into Sulphur dioxide on combustion. Emission of SO2 in atmosphere results in acid rain, corrosion in buildings and structure and cause health hazards to living beings. Coal based Power Plant are considered to be largest producer of air pollutants. Flue gas desulphurisation plant are provided in Thermal Power Stations to remove SO2 from flue gases before these are discharged into atmosphere.

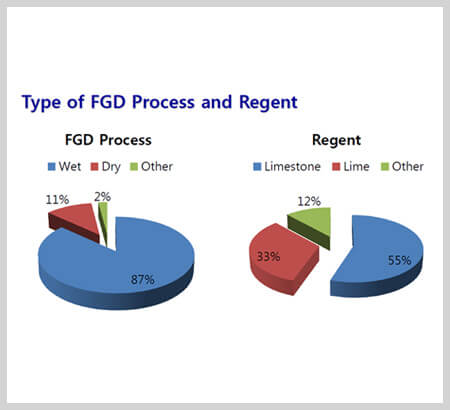

The various types of FGD techniques and their percentagewise usage in Power Plants are given below:-

As given above, Wet FGD Systems are considered to be most efficient in reducing SO2 emission in inland Coal based Power plants compared to other FGD systems. Removal of sulphur from the flue gas in Wet FGD System involves passing the gases through a Scrubber which is like a shower.

br>

Flue gases rise in Scrubber which showers water down on gas stream. The sulphur in flue gases dissolves in the water to give sulphuric acid, this way the sulphur is removed from the flue gas and gas thereupon passes up a chimney and into the atmosphere.

Sulphuric acid produced flows out of the scrubber and is neutralised with limestone (calcium carbonate) to form calcium sulphate, water and carbon dioxide. The calcium sulphate produced is known as de-sulphurated gypsum and is sold to plasterboard/plaster manufacturers. Simplified chemical reaction that takes place in Absorber Tower of limestone based Wet FGD Plant is as under: -

CaCO3 + SO2 + 3H2O+1/2 O2 = CaSO4.2H2O +CO2 +H2O

(Limestone) (In Flue gases) (oxidation) (Gypsum)

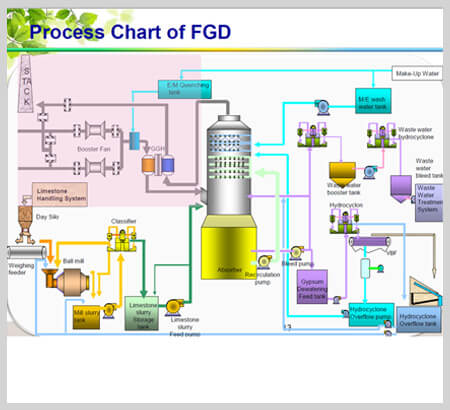

A Generic Schematic Process Flow Diagram of Flue Gas De-Sulfurization may be referred as below:-

Limestone is key and basic regent whereas Gypsum is the major tail end product of a FGD system. Thus, limestone handling and Gypsum Handling system form an important and integral part of Wet FGD Plants.

Macawber Beekay Pvt. Ltd. offers limestone and gypsum handling system for Wet FGD plants and provides integrated package for both the products as an EPC supplier.

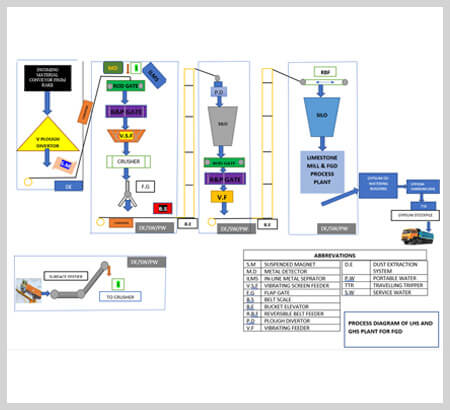

Typical flow scheme of Limestone and Gypsum handling system in Wet FGD Plant being provided by Macawber Beekay Pvt. Ltd. is depicted below:-

You will find yourself working in a true partnership that results in an incredible experience, & an end product that is the best.

Our capabilities give us a competitive edge over our

competitors. We have more to offer